Management GmbH

Nordostpark 85

D-90411 Nürnberg

+49 (0) 911 929099 - 0

info@iq-nbg.de

Aerospace Engineering

Energy Technology

Natural resources for energy generation are limited, we cannot keep exploiting our environment infinitely. Without alternative energies, future generations cannot exist in the same way as we do. We are using all our creativity to develop innovative techniques that deal responsibly with the precious resources of this earth. At the same time, we are trying to implement novel and efficient concepts for the energy industry.

We support our customers from the energy industry with the following range of services:

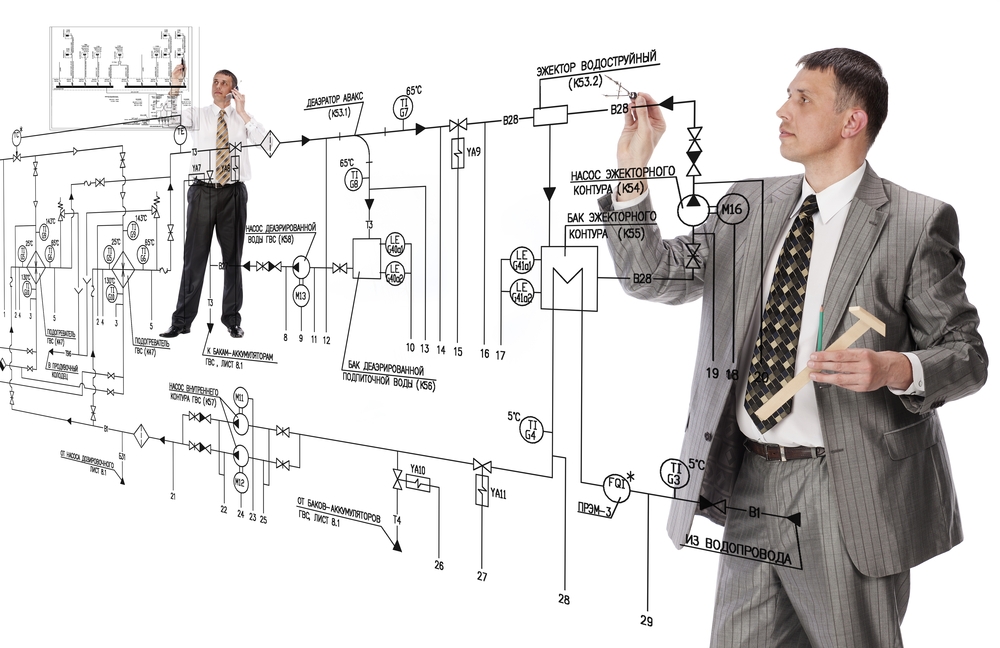

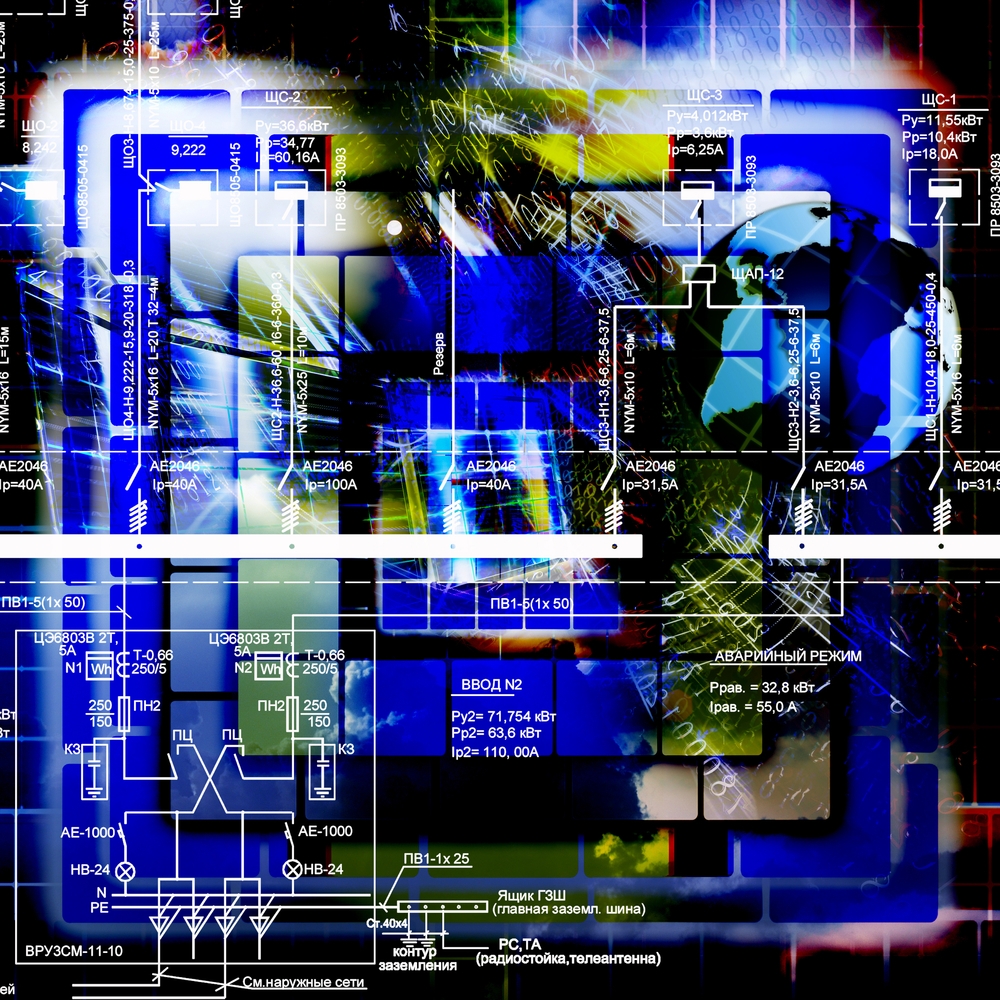

- Creation of electrical construction drawings using Elcad, Eplan, AutoCad

- Preparing quotations based on tenders

- Conceptual design, processing and commissioning of control technology and protective devices

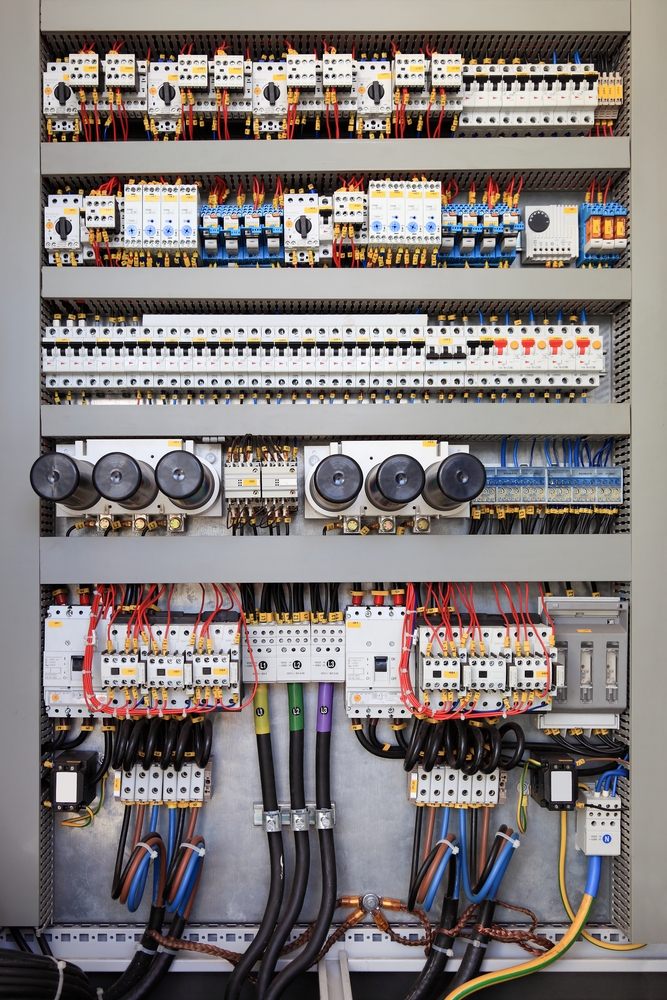

- Development of switchgears and switch housings

- Creation of circuit diagrams and circuit manuals

- Creation and revision of assembly descriptions

- Performing and evaluating simulations and tests

- Software and hardware development

- Upgrading systems through new and improved functions

- Documenting the entire project execution, from engineering to acceptance

Concrete case studies of our services in the domain of energy technology:

1. Development of microelectronics for photovoltaic inverters:

- Draft design, layout supervision, commissioning and testing of microelectronics (processors and peripherals)

- Software development under C/C++

- FPGA programming with VHDL

- Organising and performing module, integration and release tests

2. Power transmission:

- Preparation of a feasibility study on an interconnected North Sea network of European offshore wind energy facilities based on the gas-insulated transmission line for efficient, ecological and economical power transmission

- Creation of signal lists for bus coupling

- Programming in CFC for controllers

- Protective and power plant technology

- On-site commissioning

3. Process control engineering:

- Sub-project management in the fossil fuel power plants sector

- Commissioning the cooling water, chemical storage and condensate area in the power plant

- Creating different function variants for control system simulation with SPPA-T/S3000

- Management responsibility of employees for parts of the simulation project

- Creation of acceptance documents for simulator and emulator projects as well as QA documentation officer with national and international contact partners (France and Sweden)

- Creation and administration of databases, queries and screens

- Commissioning in the automotive sector for optimising technical processes taking into account the cycle times

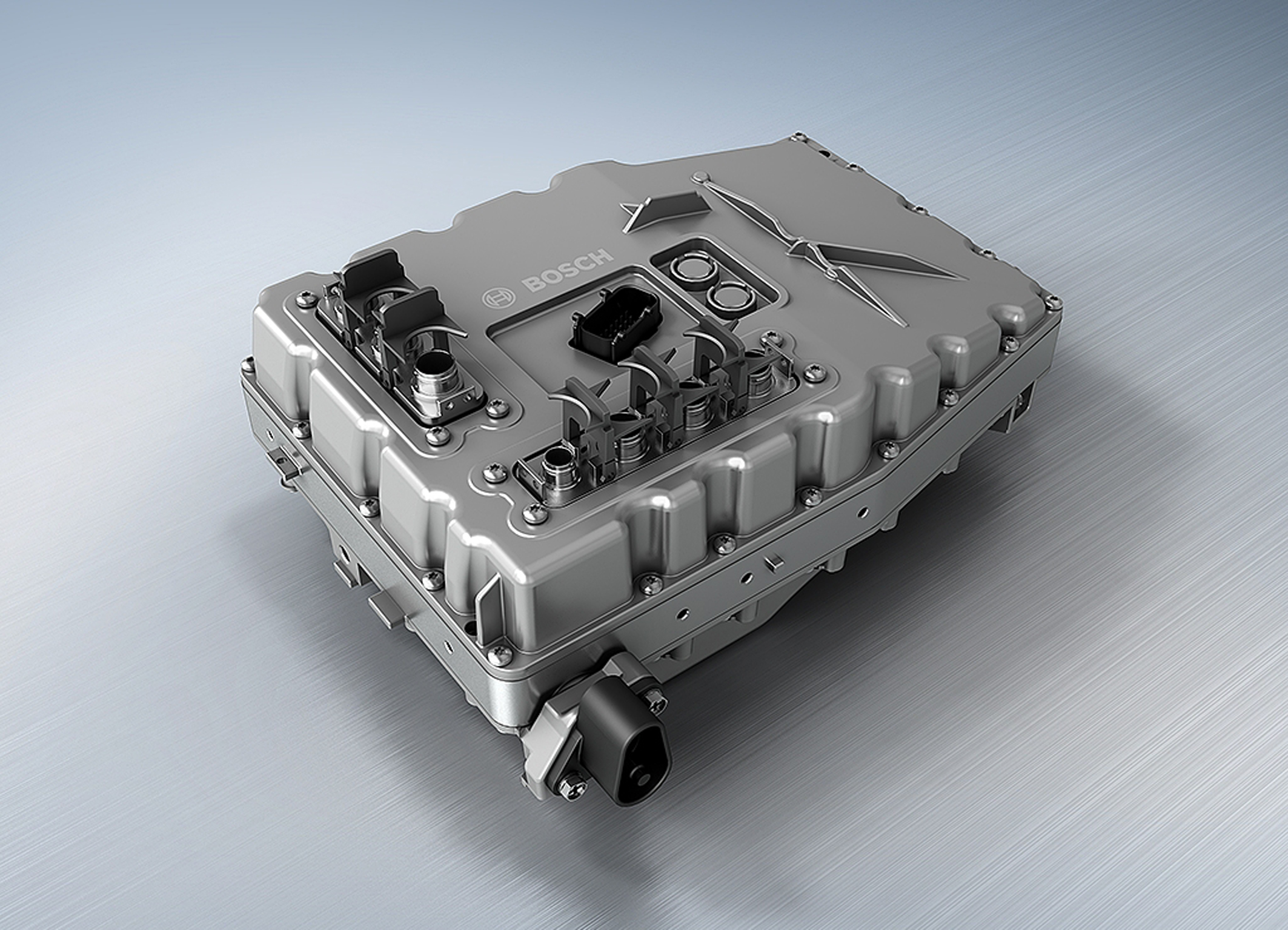

4. Engineering traction power converters for railway applications:

- Participation in project management (oPLM process)

- Creation of documentation

- Creation of circuit diagrams

- Creation of parts lists

- Creation of descriptions for devices in German and English

- Preparation of technical specifications for electrical assemblies and clarification with suppliers

- Processing customer and supplier enquiries

- Technical clarification of orders

- Support with general activities (material replenishment, orders)

- Supervision of prototype construction, production and testing facilities

- Support during type testing and system testing

- Participation in product improvement for the assembly of traction converters in flow production

5. Module development and implementation:

- Creation of building overview plans

- Project-specific adaptation of drawings for the high transformers sector using AutoCad

- Development of new and optimisation of existing systems, configurations and modules

- Creation and maintenance of documents

6. System planning:

- Responsible for project-specific clarification with external system planners

- Responsible for system planning and the building site

- Implementing system design reviews from the perspective of electrical engineering

- Preparing and updating electrotechnical system planning specifications for external system planners

- Contractual and technical clarification of interfaces to internal and external partners for electrotechnical system planning

Automotive Engineering

Automotive engineering is one of the core competencies of our range of services. For both OEMs and suppliers, we are active along the entire value chain, from the conceptual idea to the finished product. This is especially true in the bodywork, interior, chassis and drives fields.

Automotive engineering is one of the core competencies of our range of services. For both OEMs and suppliers, we are active along the entire value chain, from the conceptual idea to the finished product. This is especially true in the bodywork, interior, chassis and drives fields.

During hardware development, we support our customers with the following range of services:

- Overall project planning and coordination

- Creation and analysis of functional specifications and requirement specification sheets

- Hardware development in the field of analogue and digital circuit technology using CAE tools for control units

- Designing circuit concepts and designs using different circuit board technologies for circuit development and calculation

- Qualification and development of simulators for control units

- Supervision and coordination of hardware prototypes, as well as hardware trials and tests using suitable procedures and their documentation

- EMC measurement and subsequent optimisation

- Integration of individual components and modules into the overall system

- Documentation of the entire project execution using word processing and CASE tools

- Coordination of different departments such as production and quality planning, purchasing, software development and logistics

During software development, we support our customers with the following range of services:

- Overall project planning and coordination

- Analysis and specification of the software required

- Creation and analysis of functional specifications and requirement specification sheets

- Development and implementation of system and functional software

- Implementation of tests and measurements using modern simulation tools, as well as their documentation and subsequent verification of the existing software

- Automation of tests to be performed

- Integration of individual software components or modules into the overall system

- Documenting the entire project execution, from development to acceptance

- Coordinating different departments such as production and quality planning, purchasing, hardware development and logistics

Concrete case studies from automotive engineering:

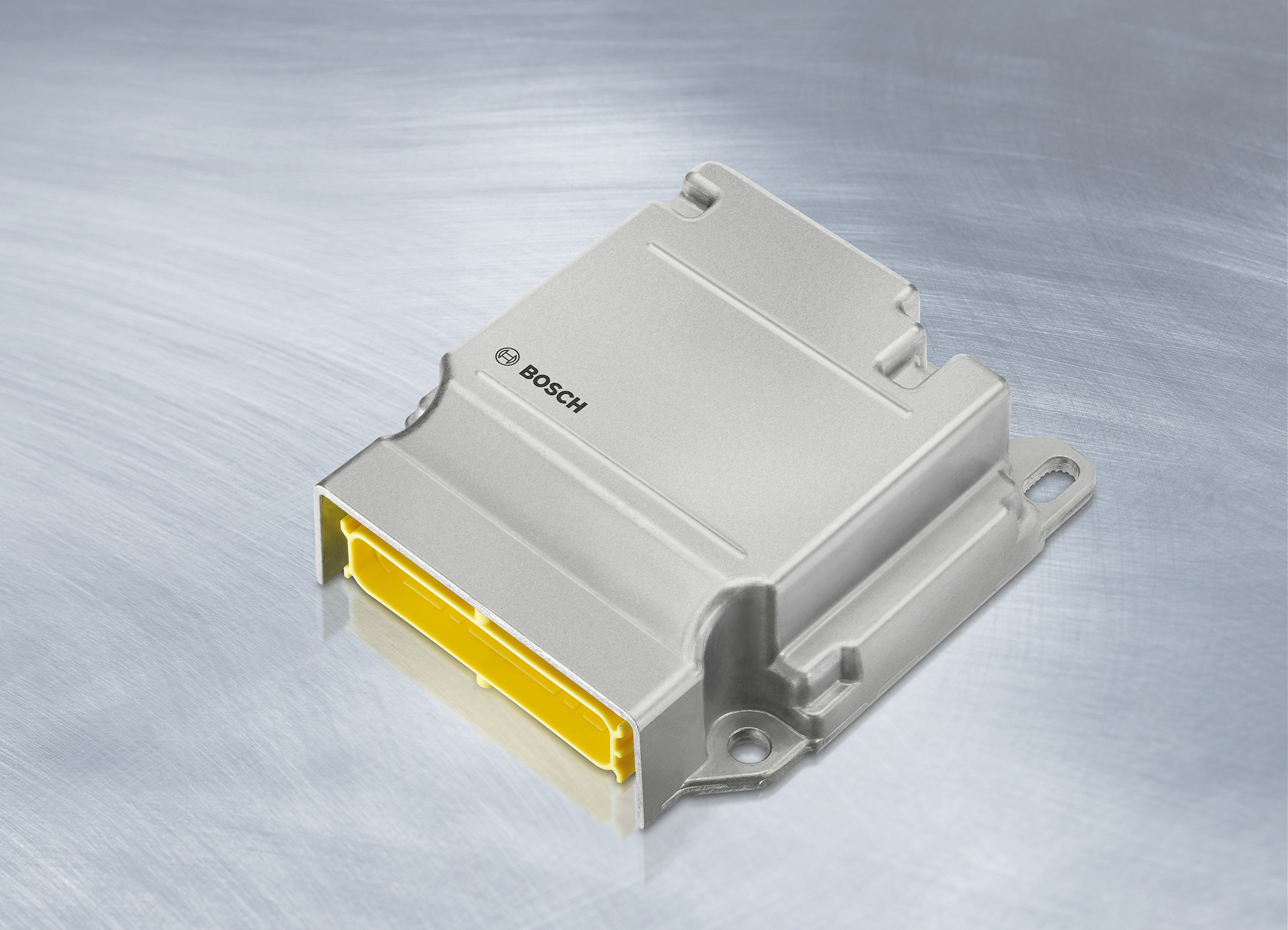

- Hardware development in the hybrid drives sector - power electronics for controlling energy flows in hybrid and electric vehicles: Fuse and tolerance calculations of circuit modules (analogue, digital, power electronics), measurement and verification, commissioning in HV laboratory, processing project-related FMEA points, documentation in DOORs, adaptation of circuit modules

- Hardware development for battery management systems used for controlling lithium-ion cells: Performing validation and verification measurements, troubleshooting and analysis of the battery pack, developing a switch box for test automation

- Software development for DCU control units: Developing the overall interface microcontroller software for several variants of a DCU control unit with integrated inertial sensors, testing and verification of the software in the overall system context

- Trials and testing of synchronous motors for steering systems: Setting up and preparing the tests in accordance with customer specifications and products, adapting and programming the measurement equipment, checking the execution of the tests, analysis and data processing, analysing acoustic data and measurements, evaluating and writing technical reports, testing and approval of prototypes before customer delivery, data processing, writing reports

- Advanced development of longitudinal dynamics of hybrid vehicles: Function development, brake recuperation operating strategy, controlling an electrical add-on vacuum pump, communication/interface definition, stability monitoring, specification for suppliers, support for the test vehicles and their design and equipping programs, monitoring part procurement and installation, coordination of conversions (ECU, HCU, Brake unit, pedal system, etc.), testing and evaluating the respective software versions, creating a test catalogue for validation, applying the functions in the test vehicles, commissioning the concept system prototypes, commissioning the developed SW versions, validation using the test catalogue created, documentation and final presentation

- Project planning and implementation of the modification to the SMART body controller for the innovative car sharing system car2go: Clarification of the project requirement, preparation of a requirement specification, clarification of the change with the supplier, commissioning the change, preparing test cases for ECU tests as per requirement specification, component test in laboratory and vehicle, preparing test documentation, performing error analyses for acute vehicle problems, performing required vehicle software updates, performing release tests on the software and documentation

Medical Technology

Medical technology, particularly in Germany, is characterised by a high innovation potential and high-quality products. The constant progress in medicine also demands innovative developments and improved processes in the field of medical technology.

The development of highly complex technical equipment, such as novel X-ray systems, radiation therapy systems, ultrasound systems or surgical robots is part of our range of services and requires a high sense of responsibility from all those involved.

During hardware development, we support our customers from the medical technology sector with the following range of services:

- Overall project planning and coordination

- Creation and analysis of functional specifications and requirement specification sheets

- Development of hardware in the field of analogue and digital circuit technology using CAE tools for medical control units

- Designing circuit concepts and designs using different circuit board technologies for circuit development and calculation

- Qualification and development of simulators for control units

- Supervision and coordination of hardware prototypes, as well as hardware trials and tests using suitable procedures and their documentation

- EMC measurement and subsequent optimisation

- Integration of individual components and modules into the overall system

- Documentation of the entire project execution using word processing and CASE tools

- Coordination of different departments such as production and quality planning, purchasing, software development and logistics

During software development, we support our customers from the medical technology sector with the following range of services:

- Overall project planning and coordination

- Analysis and specification of the software required

- Creation and analysis of functional specifications and requirement specification sheets

- Development and implementation of system and functional software

- Implementation of tests and measurements using modern simulation tools, as well as their documentation and subsequent verification of the existing software

- Automation of tests to be performed

- Integration of individual software components or modules into the overall system

- Documenting the entire project execution, from development to acceptance

- Coordinating different departments such as production and quality planning, purchasing, hardware development and logistics

Concrete case studies of services within medical technology:

- Concept development for a new test sequencer based on NI Labview, NI TestStand, and MS Access

- Creation of automatic tests for an X-ray high voltage generator cabinet with the previous test sequencer

- Procurement of measuring equipment for a manual final inspection station for a mammography system

- Creation of a manual test instruction and a manual final test station for a mammography system

- Performing various development acceptance tests for a mammography system (focus on EMC tests, as a guide from system development)

- Validation of IT hardware for use in medical technology systems

- Creation of software packages for automatic installation of PC systems in production

- Preparation and departmental execution of EMC tests on new IT hardware for use in medical technology systems

- Design, development and testing of hardware-related software for real-time operating systems

- Development and maintenance of firmware for multidetector arrays in C++

- Connecting measuring instruments to the dosimetry software

- Performing unit tests

- Preparing project documentation in English

- Creating test specifications based on design specifications

- Creating test exercises for system verification and validation

- Planning and performing system tests and system integration tests

- Developing test procedures

- Determination of test scope and depth before the start of the testing phase

- Analysis and documentation of errors that occur on the system interfaces and subsystems level

- Checking test documents

- Integration test, SW test, component test and function test for mammography devices

- Dokumentation vorbereiten und erstellen

- Preparing the testing facility (SW, HW, tools, measuring instruments)

- SW adaptation

- Performing the test

- Supervision of the endurance tests (internal, external)

- Processing and logging intermediate and test results

- Installing software updates on X-ray systems

- Starting endurance tests

- Archiving the log files

- Evaluating the endurance tests using ArtisLogSniffer

- Analysis of errors that occur

- Creating and validating change requests

- Creating error statistics

Automation Technology

In these times of globalisation, automation technology is indispensable for increasing productivity and competitiveness. Quality, costs and time are essential factors in rationalising almost all processes. For machine manufacturers and system operators, it is crucial to reduce the time from the idea to the finished product to a minimum with maximum flexibility.

In these times of globalisation, automation technology is indispensable for increasing productivity and competitiveness. Quality, costs and time are essential factors in rationalising almost all processes. For machine manufacturers and system operators, it is crucial to reduce the time from the idea to the finished product to a minimum with maximum flexibility.

We have acquired extensive know-how through several years of involvement in automation technology. Our main focus is on automation technology, drive and control technology, process visualisation and measurement data acquisition, especially in the processing industry and in special machine construction.

Automation technology is important for almost all processes we deal with today: These are integrated, for example, in production engineering, robotics, automotive engineering, the control systems of machines in industry and at home. Measurement and automation technology solutions especially enable the aspects of safety, environmental protection and resource conservation, as well as product intelligence and usability within processes.

Since we are fundamentally not bound to any particular make of equipment, we can operate various PLC systems.

Range of project planning services:

In the field of project planning, we are happy to assist you in the following areas:

- Design and implementation of the objective

- Specification of the mechanical structure of module racks

- Layout of electrical calculations

- Creation of parts lists, as well as measurement and type test protocols

- Preparation, evaluation and documentation of data for order processing

Range of electrical construction services:

We use the following CAE systems for electrical design:

- EPLAN

- ELCAD

- WSCAD

Programming:

A wide variety of hardware is used to implement your optimum control system. By using different parametrisation and programming languages, as well as the most modern software tools we create:

A wide variety of hardware is used to implement your optimum control system. By using different parametrisation and programming languages, as well as the most modern software tools we create:

- PLC controllers e.g. based on the S5 or S7 family from Siemens

- CNC controllers of the SINUMERIK family from Siemens

- Control systems with state-of-the-art drive systems such as MotionControl, CAN-/Profi- or Interbus

- Conventional small control systems

- Pro Tool/Pro, COROS/LSB, WinCC

Range of commissioning services:

We offer you support for planning and project engineering your systems. Together with you, we create a specification sheet, plan and follow the project in terms of hardware and software. Our experienced project engineers accompany you through the entire project planning phase. Use our experience to successfully implement your automation solution.

Concrete case studies of services within automation technology:

- Independent commissioning, troubleshooting and repairs to SIMOVERT MV

- Commissioning of SINAMICS low voltage converters

- SIMOVERT ML2 medium-voltage converters

- Implementation of worldwide commissioning and de-escalation operations

- Description of the software requirements

- Creation of the software requirement specification sheet for the time-controlled bus system of a PLC with 12 signal modules

- Description of the TTCAN system matrix, master and slave software architecture, and interface for PROFINET

- Creation of sequence diagrams and state machines from the TTCAN protocol using the “Visio” program

- CAN bus programming

- Programming a TTCAN system matrix for 12 signal modules with the “IAR Compiler” for ARM microcontrollers

- Using the CANalyzer analysis tool for CAN messages

- Internal order processing

- Technical clarification of orders

- Creation and revision of material parts lists, documentation, layout plans and dimensional drawings, system-specific data sheets, circuit diagrams

- Coordination of production and test facility

- Support for internal customers and suppliers

Inspection of testing and processing facilities for optimisation approaches, preparation and realisation of improvements on the basis of planning, evaluating economic efficiency, product quality, technical innovation and availability:

- Recording, processing, evaluating and eliminating control engineering problems for relevant fields

- Preparation of decision bases and presentation of alternative solutions with regard to technical execution, costs, reliability, process safety and environmental influences

- Evaluation of the individual possible solutions, coordination of these with the affected bodies and preparation of recommendations for decisions

- Participation in project teams by developing, evaluating and implementing testing and processing facilities

- Creation of requirement profiles, technical implementation specifications and evaluation of alternative designs proposed by the tendering parties

- Creation of functional specification sheets or service specifications

- Preparation of project schedules and coordination with related parties

- Monitoring of deadlines, the quality of execution, technical function and compliance with regulations during implementation

- Implementation and management of sub-project coordination of overall projects

- Assumption of the responsible, legal coordination function in compliance with the German Accident Prevention Regulations (UVV) for the transferred projects

- Commissioning systems, ensuring production capability and carrying out acceptance tests with the involvement of all affected specialist departments

- Preparing acceptance protocols and arranging for faults and complaints to be resolved

- Assisting with maintenance and resolving complicated faults in systems

- Preparation of documentation and system manuals

- Responsibly taking measures to safeguard production on systems during production-free periods

- Supervision of the production start-up process